Si Gradient Super Core JNSF™

-

High Saturation Flux Density

-

Low Iron Loss at High Frequency

6.5% Si steel is an excellent core material for high frequency applications because its resistivity is nearly 2 times higher than that of 3% Si steel and heat generation is small due to its small eddy current loss. On the other hand, 3% Si steel has the advantage of a higher saturation flux density in comparison with 6.5% Si steel due to its smaller content of Si, which is a nonmagnetic element.

With conventional technology, it was not possible to satisfy both high saturation flux density nearly equal to that of 3% Si steel and low iron loss at high frequency on the same level as 6.5% Si steel. Therefore, JFE Steel developed a new material, Gradient Si Super CoreTM JNSF, which satisfies both high saturation flux density and low iron loss at high frequency1, 2).

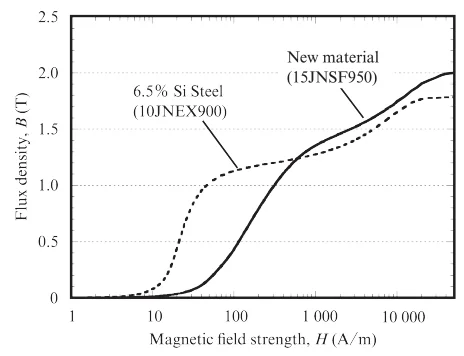

Fig. 1 Direct current magnetization curve

Figure 1 shows the direct current magnetization curves of the developed steel, 15JNSF950 (Thickness: 0.15 mm) and the 6.5% Si steel sheet 10JNEX900 (Thickness: 0.1 mm). Because 15JNSF950 has a low concentration of Si in the sheet center of thickness, its saturation flux density shows a high value (approx. 2.0 T) nearly equal to that of 3% Si steel.

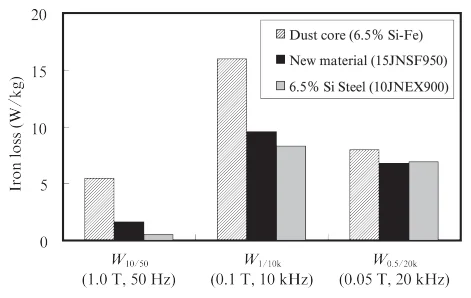

Fig. 2 Iron loss of the materials

Figure 2 shows the iron loss of 15JNSF950 and 10JNEX900 and a dust core of 6.5% Si steel. Dust cores are produced by molding pure iron powder or Si steel powder with binder, and in this study the dust core of 6.5% Si-Fe powder, which shows excellent performance even among the dust cores, was used as a comparison material. When compared under the magnetic excitation condition of a frequency of 50 Hz, the iron loss of 15JNSF950 was larger than that of 10JNEX900 but was quite small in comparison with the dust core. On the other hand, at 10 kHz, the difference between the iron loss of 15JNSF950 and 10JNEX900 decreased, and at 20 kHz, 15JNSF950 shows the lowest iron loss even thicker material thickness. This is because eddy current loss decreased due to the steep Si concentration gradient in the sheet thickness direction, and this effect becomes remarkable under high frequency excitation, in which eddy current loss is the controlling factor of iron loss1).

In other words, 15JNSF950 is a material that satisfies both high saturation flux density nearly equal to that of 3% Si steel and low iron loss at high frequency on the same level as 6.5% Si steel.

In high frequency reactors which are used in airconditioners, power conditioners for solar power systems, onboard power supplies for hybrid electric vehicles (HEV) and similar applications, the current includes high frequencies from several of kilohertzes to several tens of kilohertzes. Therefore, in order to avoid heat generation in the reactor, low iron loss at high frequency is demanded in the core material. Moreover, when the current increases and the flux density in the core material approaches saturation, reactor inductance drops sharply, and there is a danger that the electrical device may be damaged. For this reason, high saturation flux density is also demanded in the core material.15JNSF950, which has a high saturation flux density and shows low iron loss at high frequency, is suitable for applications of this type, and is an advantageous material for downsizing and high efficiency in reactors.

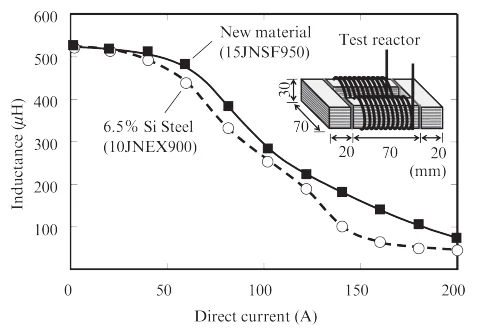

Fig. 3 Direct current bias characteristics of the test reactors

Reactors of the same type were produced by using 10JNEX900 and 15JNSF950, and Fig. 3 shows their direct current bias charasteristics. Overall, it can be understood that 15JNSF950 shows higher inductance. Because of the high saturation flux density of 15JNSF950, the decrease of inductance in the high current region is moderate. Some reactors require high inductance in higher current region than a rated value; 15JNSF950 is considered well-suited to such applications. Because the iron loss of 15JNSF950 at commercial frequency is extremely small in comparison with that of the dust core (6.5% Si), as shown in Fig. 2, 15JNSF950 is also considered to be a suitable core material for AC reactors, in which commercial alternating current is superimposed on a high frequency.

15JNSF950, which was developed by JFE Steel, is a material which satisfies both high saturation flux density nearly equal to that of 3% Si steel and low iron loss at high frequency on the same level as 6.5% Si steel. 15JNSF950 is suitable for use in the core materials of high frequency reactors, etc. Application in the field of power electronics, where the trend toward higher frequencies is progressing, is also expected in the future.

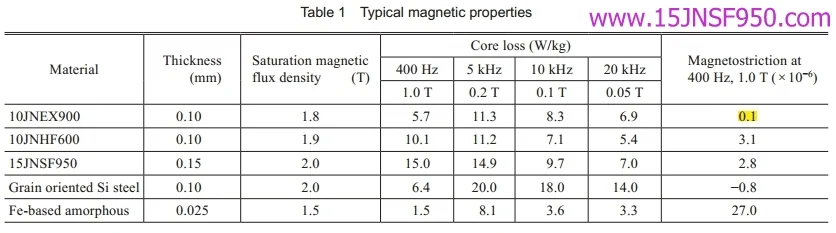

JFE Super Core 10JNEX900 10JNHF600 15JNSF950 Typical magnetic properties comparison